In 2022, the HSE, Britain’s national workplace health and safety regulator, reported three significant arc flash incidents within the UK. These resulted in costly business penalties, severe employee injuries, and national media coverage. Each accused business was found guilty of breaching the Health and Safety at Work Act. In one incident, the guilty party received a £1 million fine.

Could such devastating incidents have been avoided?

The short answer – Yes. This is the fundamental principle of an Arc Flash assessment. Arc Flash assessments are responsible for reporting and mitigating a site’s energy levels, recommending the appropriate Personal Protective Equipment (PPE) alongside alerting, notifying, and training the onsite workers of the potential hazards. Businesses are responsible for ensuring their Arc Flash assessments are up-to-date and accurate. In each case noted by the HSE, an Arc Flash assessment would have decreased incident probability, protecting the workers’ lives and firms’ cash!

The Enspec team were recently contracted to perform an Arc Flash and Protection Coordination Studies for a +300MVA power plant in UK. To do this, we took the following steps:

- The project started with Data Collection and Building the Model.

- Maximum and Minimum Short circuit current values were determined considering different network modes of operation.

- A Protection Coordination study was conducted, starting from the Medium Voltage Substation to the Low Voltage Distribution Buses.

- We checked existing protection settings and supplied new recommended settings to enhance coordination time intervals and ensure adequate zone protection.

- A detailed Arc Flash study was conducted in line with the Std. IEEE 1584-2018 for all applicable electrical equipment.

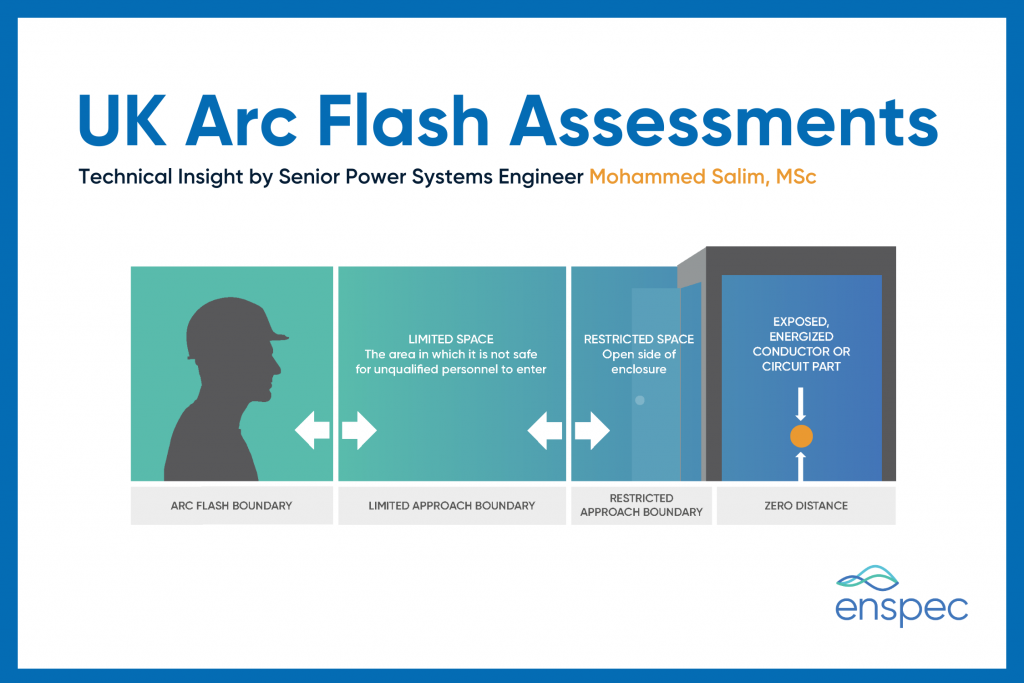

- Incident energy levels and Arc Flash Boundaries (See Figure 1)were evaluated for all network modes of operation to capture the worst-case results.

Figure 1: Visualisation of Arc Flash Boundaries.

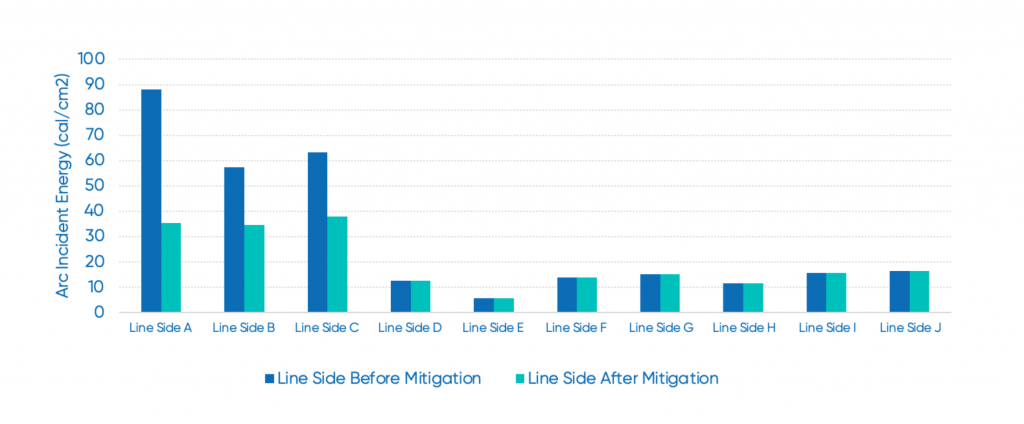

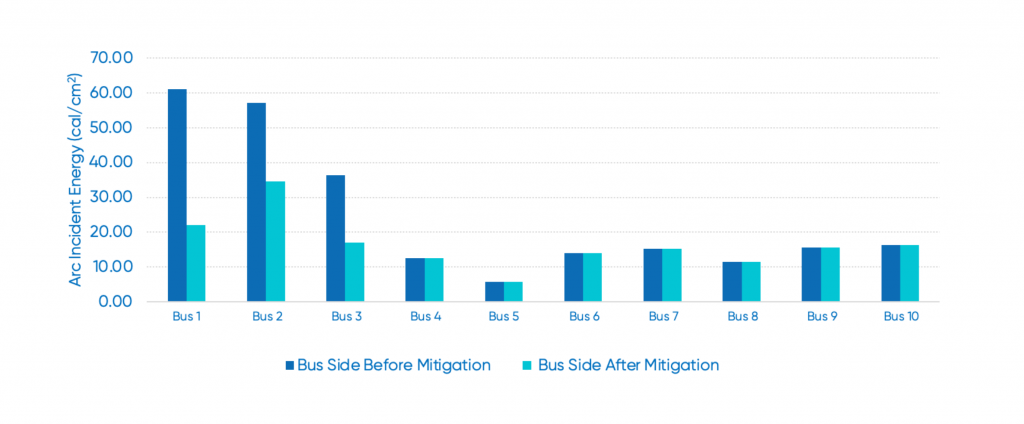

- Wherever the Incident energy level exceeded the cal/cm2 limit, several mitigation solutions were recommended to reduce the Incident energies. Before and after mitigation results are shown in Figures 2 and 3. One of the recommended measures was to replace an existing electromechanical relay with a new micro-processer-based relay, which is compatible to be equipped with an Energy Reduction Maintenance Switch (ERMS). The ERMS will initiate/ activate a second setting group that allows no intentional delay to reduce the clearing time under the maintenance mode of operation without compromising the coordination during normal operation.

Figure 2: Line Side Mitigation Calculations before and after.

Figure 3: Bus Side Mitigation Calculations before and after

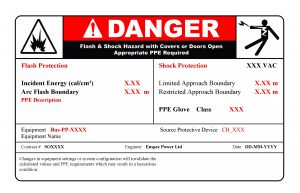

- Arc Flash Labels were provided. (See Figure 4)

Figure 4: Arc Flash Label Example

We’ll be following up the breakdown with a white paper and case study, so make sure to subscribe so you can get all the details.

Contact us to conduct Arc Flash and Protection Coordination Studies for your Network.