The Problem in Detail

Enspec were retained to carry out a Protection Coordination and Arc Flash study for a UK manufacturing site. The main purpose of the study was to provide labels and PPE recommendations for the switchgear to inform people working within the switch room of the safety standards. As part of this Enspec carried out a full protection coordination study as the relay settings are a big factor when calculating the Arc Flash incident energy.

Finding the Solution

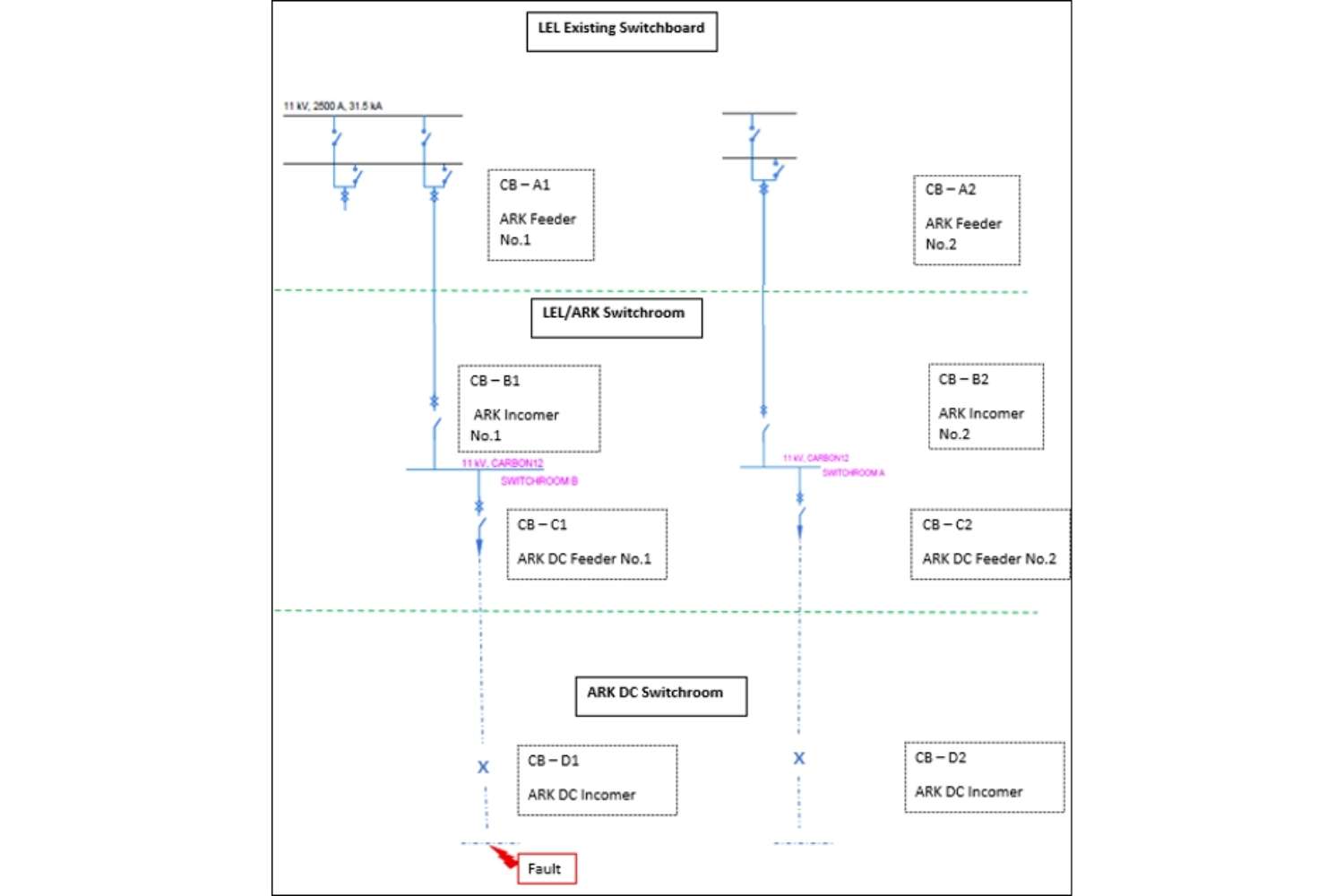

Enspec worked with the customer to collect key site information such as single line diagrams, fault levels, protection devices and operational scenarios. We then used this information to model the site in ETAP and to input the existing protection device settings.

Making it all Work

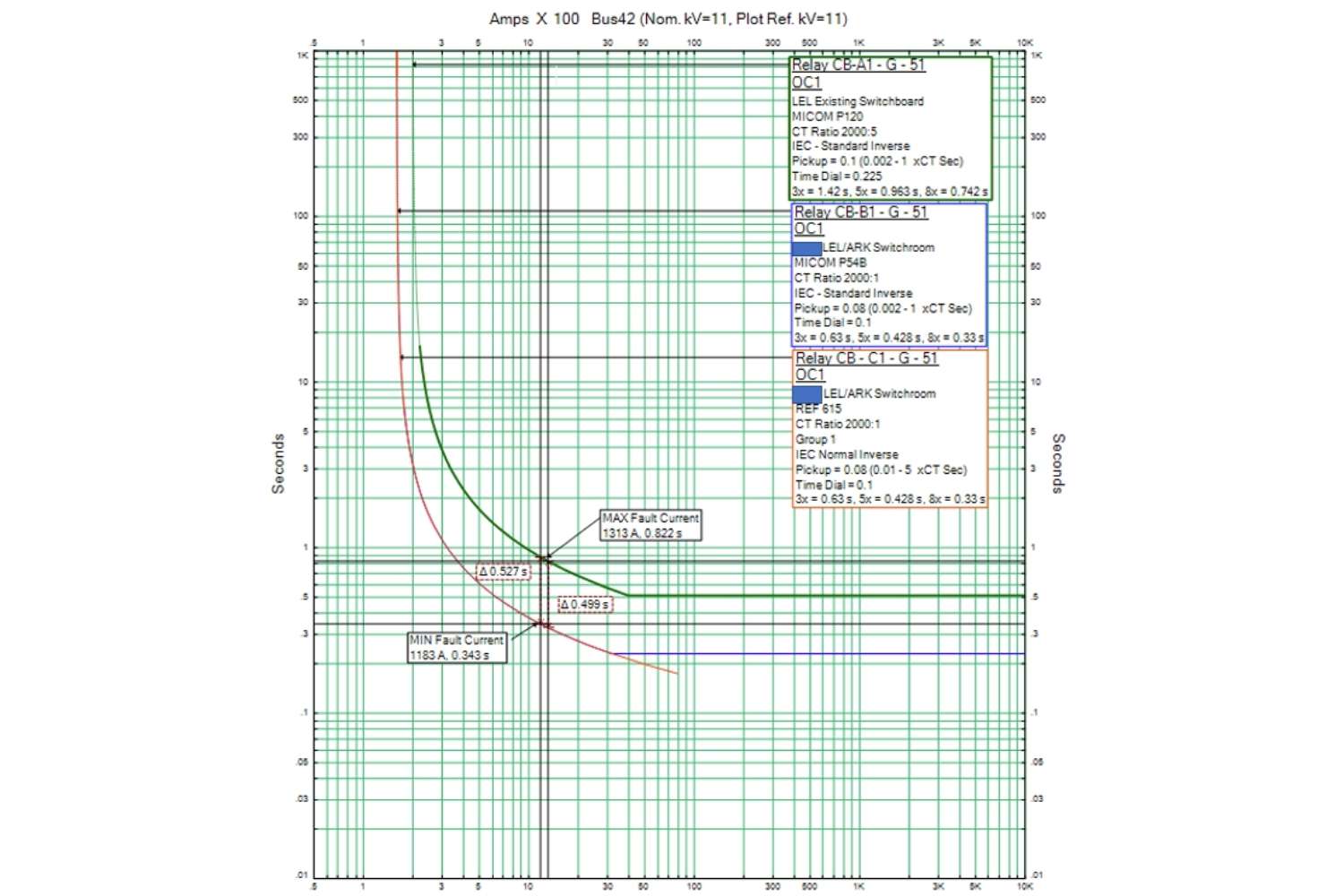

The ETAP model was then used to run through various settings for each protection device in order to obtain total discrimination between devices. Protection devices closer to local loads should be the first to trip in the event of a fault so that other equipment or even the entire site is not tripped unnecessarily. There are a number of different protection curves and settings for each type of device - these were all used to give the correct characteristic in relation to other devices.

What that means for the project now

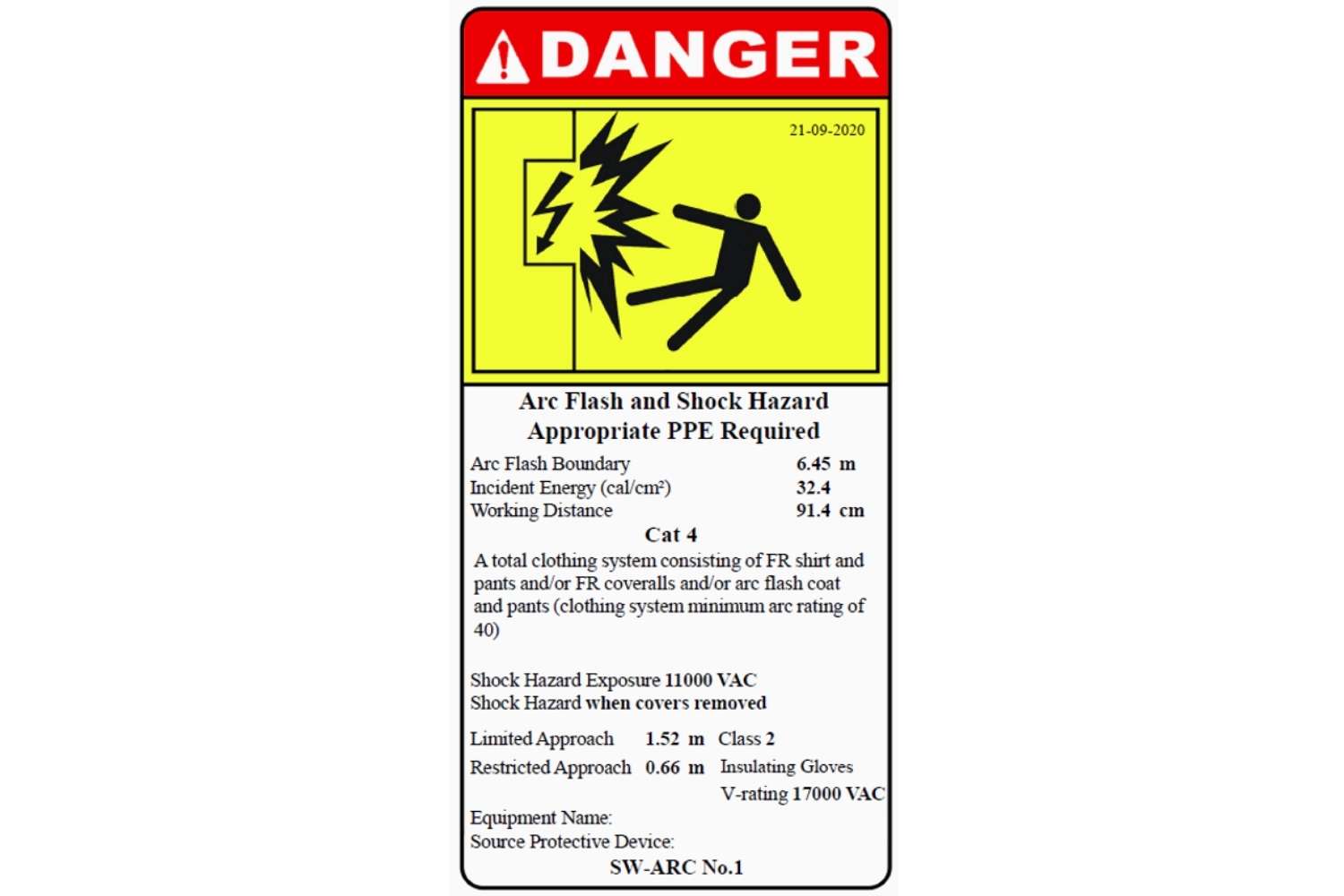

Once the protection coordination study had been carried out the ETAP model was used to carry out an Arc Flash study. This study looked at the possible fault cases and calculated the worst case incident energy along with arc flash categories, working distances and PPE requirements. These labels will then be affixed to the site switchgear to inform workers of the safety requirements.

Find out more about Power System Studies here.

An Arc Flash Study, UK Manufacturing

Send download link to: