The Problem in Detail

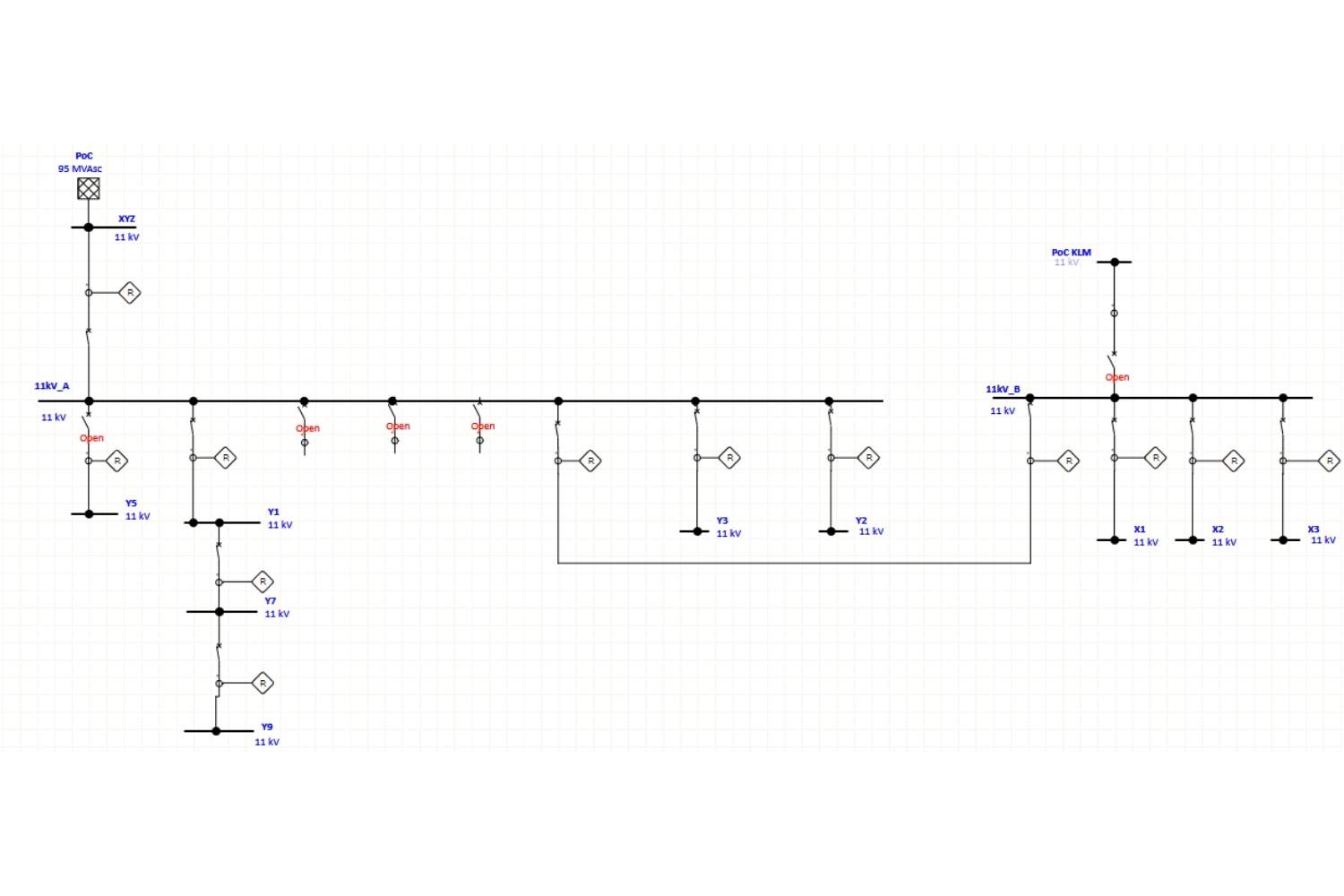

Enspec were retained to carry out a Protection Coordination study for a UK manufacturing plant. The site had some existing protection device settings as well as settings for the DNO feeder breakers. We were required to model the site and protection devices and decide on settings for the on-site devices that would ensure for total discrimination.

Finding the Solution

Enspec worked with the customer to collect key site information such as single line diagrams, fault levels, protection devices and operational scenarios. We then used this information to model the site in ETAP and to input the existing protection device settings.

Making it all Work

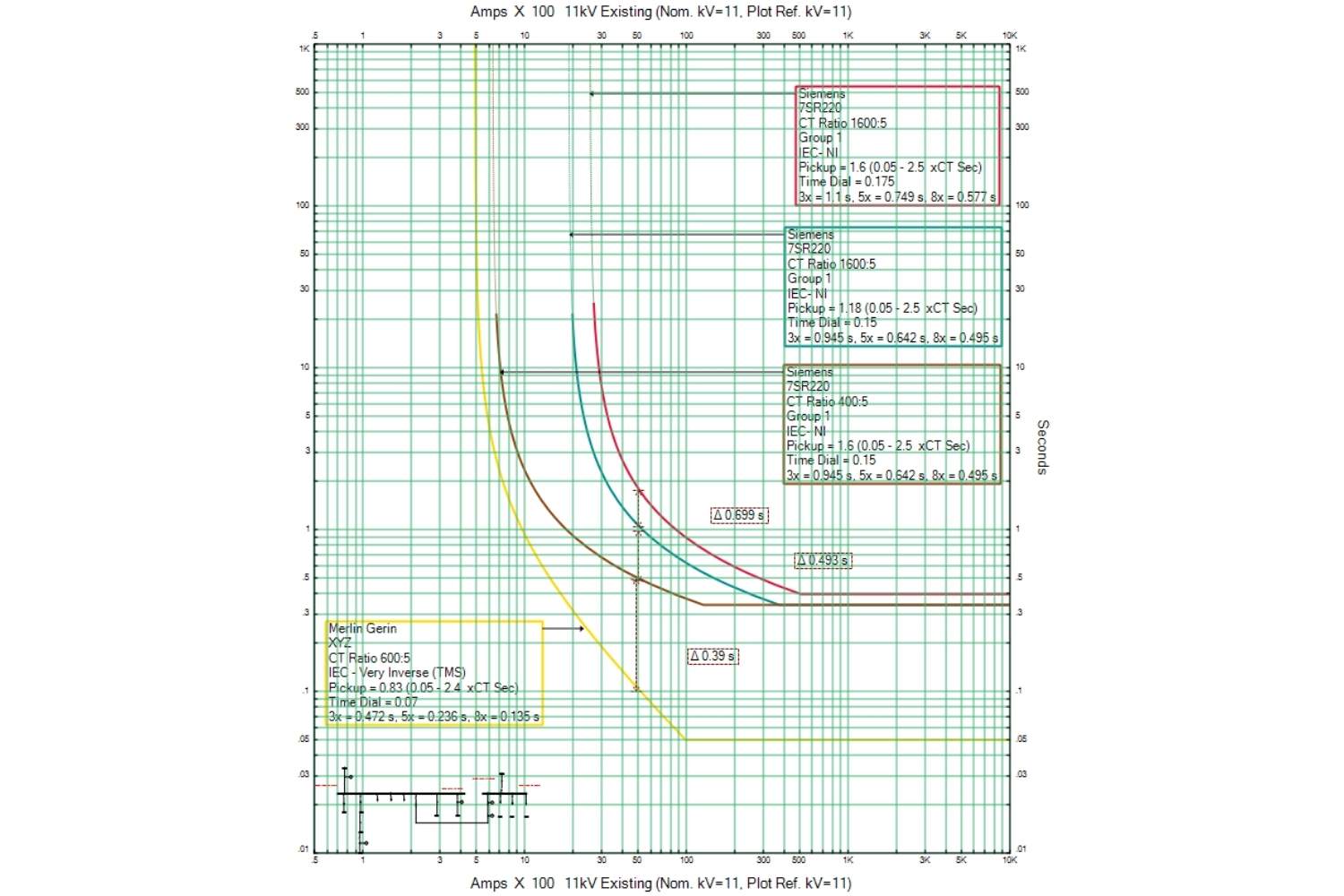

The ETAP model was then used to run through various settings for each protection device in order to obtain total discrimination between devices. Protection devices closer to local loads should be the first to trip in the event of a fault so that other equipment or even the entire site is not tripped unnecessarily. There are a number of different protection curves and settings for each type of device - these were all used to give the correct characteristic in relation to other devices.

What that means for the project now

The final settings devised by Enspec ensured for total discrimination between downstream and upstream devices. The presented report included the final graph showing the DNO, existing and Enspec proposed settings and how much discrimination was allowed for. This allowed our customer to carry out the on-site commissioning on-time and safely.

Find out more about Power System Studies here.

Protection Grading Study for UK Manufacturing.

Send download link to: