The Problem in Detail

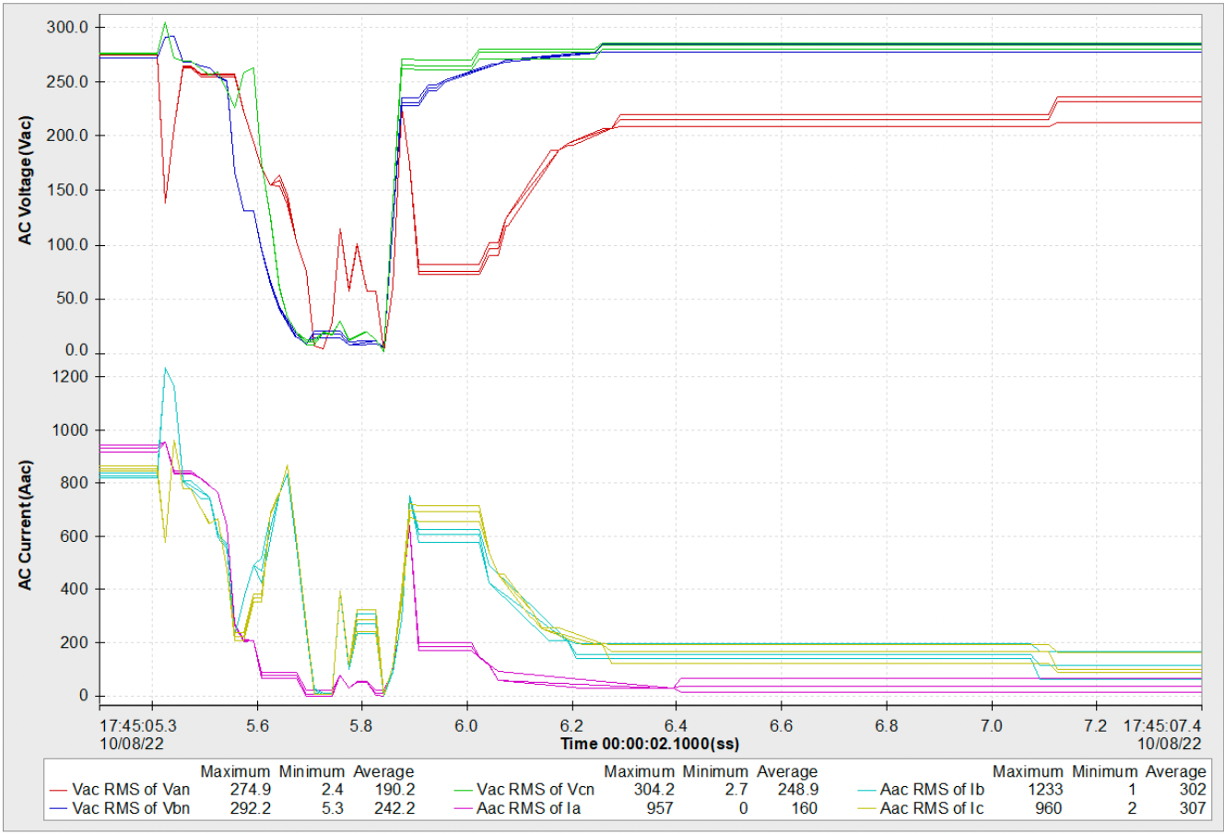

Voltage fluctuations disrupted Kedrion Biopharma's plasma-fractionation plant in Mellville, NY, causing equipment malfunctions and product wastage. Fluctuations, including dips as low as 17-18 volts and swells beyond acceptable limits, jeopardised critical manufacturing processes, violating operational voltage requirements.

Finding the Solution

Enspec diagnosed the root cause, identifying external grid instability. We proposed an integrated uninterruptible power supply (UPS) system using flywheel technology, known for its rapid response and high reliability in providing continuous power.

Making it all Work

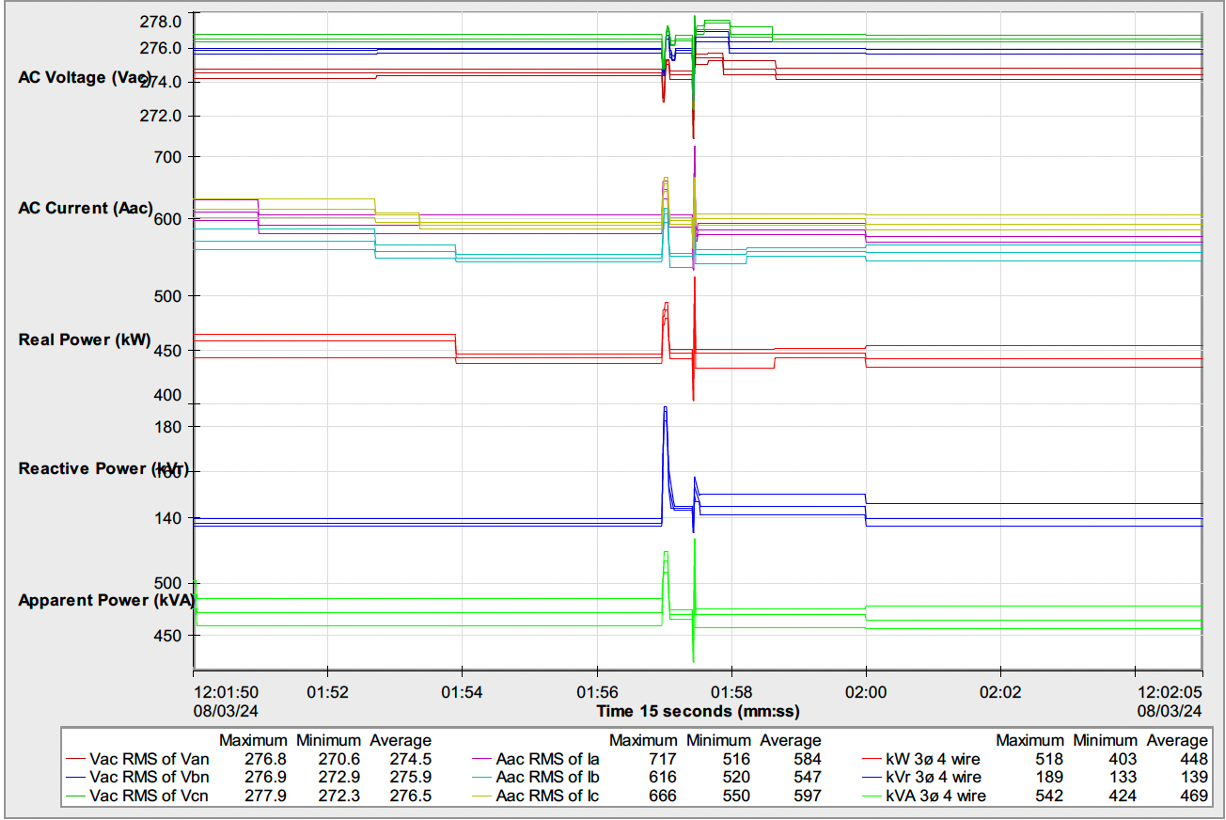

Rigorous commissioning tests validated the UPS system's efficacy in sustaining voltage during outages. Simulating grid loss and seamlessly transitioning between the UPS and backup generators confirmed reliability. Addressing concerns related to accurate power metering ensured system integration and functionality within Kedrion's facility.

What that means for the project now

The successful deployment of the flywheel UPS system ensures uninterrupted power supply for critical manufacturing processes, minimising disruptions and risks to product quality. Collaborative efforts underscore the importance of proactive power quality management when it comes to mitigating voltage interruptions and investing in robust energy storage solutions for continuous operations in critical manufacturing environments.

Find out more about Enspec Power here.

Mitigating Voltage Interruptions for Kedrion Biopharma – A Case Study

Send download link to: